The PureLED System

The PureLED Modular LED System

PureLED Resources

- Plug-In Circuit Board

- Protection Circuits

- Safetouch Gimbal

- Beam Angles & Optics

- Debunking LEDs

- PureLED Specifications

- Ultra Specifications

Plug-In Circuit Board

Truly the heart of the Pure LED system is Hunza’s Plug-and-Play circuit board that allows the LED to easily be unplugged and replaced in the field. The unique design delivers maximum performance from the market-leading Cree LED chips and, in the event of an LED problem, the Plug-and-Play feature allows easy replacement or upgrade of the LED chip.

You can see from the diagram how the LED board is secured to the electronics “pot” underneath the machined aluminium heat sink. The two screws serve a dual purpose, ensuring secure installation of the board, while also acting as the contacts for conducting the electrical current.

The LED board has a coating of a special compound on the underside surface to maximise heat-transfer efficiently. The aluminium heat-sink fits snugly inside the fixtures body, so heat is transferred quickly and efficiently away from the LED chips. This system enables Hunza to obtain maximum light output from the LED without compromising the life of the component.

Protection Circuits

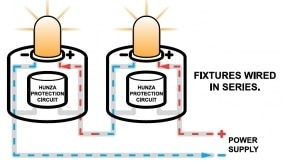

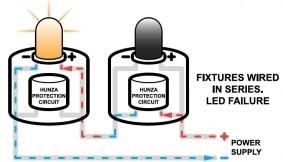

Hunza includes advanced protection circuitry in 6W and 4W Series version PureLED light engines to help guard against damage from incorrect wiring and simplify the task of identifying a failed LED.

Each of these light engines include a removable “series pot” plugged into the back of the fixture, which houses a circuit board.

This board carries the necessary wiring and components to deliver power to the LED chip. However, it also includes additional components to protect the system and simplify maintenance.

One of these components is called an LED shunt, which diverts power around the LED chip, should it fail for any reason. Normally a failure like this will result in every fixture in the series losing power.

The Hunza LED shunt ensures that the rest of the fixtures stay working, making it simple to identify the failed LED, as well as keeping most of the lights on until the damaged one is fixed.

Safetouch Gimbal

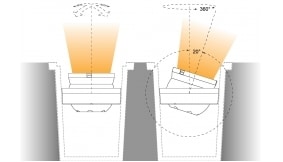

Hunza has revolutionised in-ground LED technology by developing the unique SafeTouch Gimbal system, as used in the SafeTouch 50, SafeTouch 100 and SafeTouch 150 product ranges.

The LED board is mounted on a spherical, aluminium “eyeball” gimbal that swivels inside a precision-machined heat-sink. Thereby maximising the surface area available for heat transfer, while providing 360 degree rotation and 0-20 degree elevation adjustment in any direction.

Heat is readily transferred from the LED module into the heavy duty fixture body, and from there into the surrounding installation medium. The heat is further reduced by means of air flow channels spaced around the perimeter of the outer collar. This is demonstrated in the diagrams below.

This allows the LED chip to operate at higher current levels – with a resulting increase in lumen output – while staying with the safe temperature limits specified by Cree. The unique swivel design of the eyeball allows the LED module to be aimed in any direction and then locking in place. This provides full 360 degree rotation and 0-20 degree elevation adjustment.

Hunza uses a single light source – Cree COB Module – in all the Safetouch Gimbal modules, to minimise the luminaire size and achieve a highly elegant and attractive appearance.

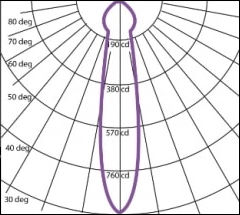

Beam Angles & Optics

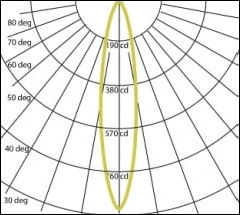

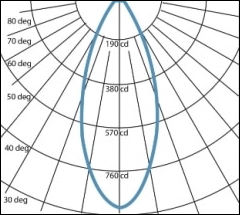

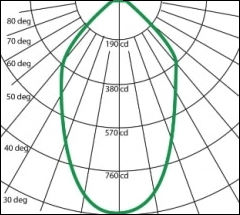

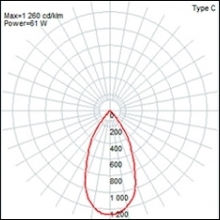

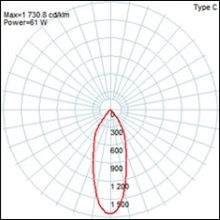

Ultra and ST150:

L-R 22°, 33° & 51°

L-R Asymetric (ST150 only) & 13° (Ultra only)

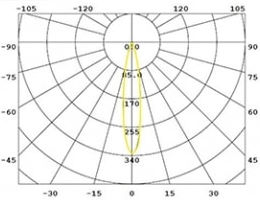

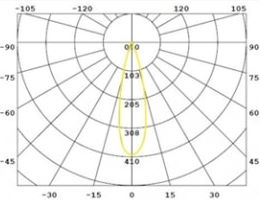

Arch Bollard:

L-R Type 4 Asymetric & Type 2 Asymetric

PureLED:

L-R 15°, 25°, 38° & 60°

The 25° is similar to the 38° apart from being slightly more frosted

High Power & ST50:

L-R 15°, 30° & 40°

Ultra 35 & ST100:

L-R 13°, 20°, 25° & 34°

RGBW Ultra 35, ST100 & ST150:

L-R 13°, 30° & 50°

Debunking LEDs

Facts:

All LEDs are dimmable

Halogen lamps produce more heat

FACT – Tungsten lamps produce 2% light and 98% heat. LEDs produce approximately 30% light and 70% heat.

Soviet inventor Oleg Loosev invented the first LED in 1927

FACT – However, LEDs were not commercially used until 1968. The current blue version LED with phosphor over the top was invented in Japan in 1992.

There are 2 types of LED drivers

FACT – There are constant current and constant voltage drivers. Constant current is used to wire LEDs in series. This is the way Christmas lights are connected. Constant voltage is used for LEDs that have a built in low voltage driver.

Myths:

A 10 watt LED will produce more light than a 6 watt LED

MYTH – This is a major error made by most people. If an LED requires 10 watts to power it, this does not mean that it produces more light than a 6 watt LED.

Any driver will power a string of LEDs

MYTH – Each LED has two specifications that must be taken into account. The first is forward voltage (vF) and the second is its maximum current rating measure in milliamps (mA). As an example Cree manufacture a MTG-2 LED. It is a 6vF (forward volt) with a maximum drive current of 2000mA, provided that the heat sink will not allow the LED to exceed 105°C at its junction point.

LEDs don't produce much heat

MYTH – LEDs produce heat in a very confined space (the foot print of the LED itself). If the LED requires 6 watts to operate then about 3.6 watts is wasted as heat.

There is no benefit in wiring to wire LEDs in series

MYTH – There is a great deal of money to be saved by wiring in series. As the driver is a constant current device it will compensate for the volt drop in the cable as a function of its design. Therefore much smaller cables can be used compared to parallel wiring. Parallel wiring requires each light fitting to have its own built-in driver (a constant current device) plus it requires considerably larger cables (which make wiring connections much more difficult) to compensate for voltage drop over longer distances.

You can connect a string of LEDs to a live driver

MYTH – This is called ‘Hot Plugging”. If the LED driver is connected to the mains before connecting the LEDs it will instantly output its maximum voltage and current thereby blowing up the LEDs.

You can use a transformer if you don't have a driver

You do not need to worry about what polarity the LED connections are

MYTH – LEDs are a one-shot opportunity to do it right. If the positive wire is connected to the negative side of the LED or vice versa it will seriously damage the LED. It may not destroy the LED immediately but it will certainly shorten the life of the LED and may reduce the light output.

PureLED Specifications

Hunza PureLED is a modular LED system designed to provide the ultimate combination of light output, illumination control and long-term performance from an outdoor-rated, sealed luminaire. It uses a single chip with high performance optics to provide a more pleasing aesthetic. There is a PureLED option for most luminaires in the Hunza product range.

Please see individual specification sheets for information on the LED options available.

Cree XHP50-2 Euro Light Engine

| LED Chip: | Cree XPG-3 Plug and Play, field replaceable PCB boards |

| Output: | 70 lumens @ 350mA | 120 lumens @ 700mA |

| Lumens Per Watt: | 70 lumens @ 1 watt | 60 lumens @ 2 watts |

| Colour Temp: | 2700K, 3000K, 40 00K, Red, Blue, Green and Amber |

| CRI Warm White (3000°K): | 85+ |

Cree XHP50-2 Euro Light Engine

| LED Chip: | Cree XHP50-2 Plug and Play, field replaceable PCB boards |

| Output: | 420 lumens @ 700mA |

| Lumens Per Watt: | 105 lumens @ 4 watts |

| Colour Temp: | 2700K, 3000K, 40 00K, Red, Blue, Green and Amber |

| CRI Warm White (3000°K): | 85+ |

Cree XHP50-2 Light Engine

| LED Chip: | Cree XHP50-2 Plug and Play, field replaceable PCB boards |

| Output: | 600 lumens @ 1050mA |

| Lumens Per Watt: | 100 lumens @ 6 watts |

| Colour Temp: | 2700K, 3000K, 40 00K, Red, Blue, Green and Amber |

| CRI Warm White (3000°K): | 85+ |

High Power Light Engine

| LED Chip: | Cree CXA1530 Plug and Play, field replaceable PCB boards |

| Output: | 1100 lumens @ 700mA |

| Lumens Per Watt: | 92 lumens @ 12 watts |

| Colour Temp: | 2700K, 3000K and 4000K |

| CRI Warm White (3000°K): | 85+ |

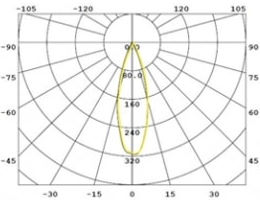

15° TIR Lens

27° TIR Lens

38° TIR Lens

60° TIR Lens

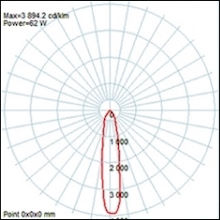

Ultra Specifications

Ultra Power Light Engine

| LED Chip: | Cree CXA Plug and Play, field replaceable PCB boards |

| Output: | 5000 lumens @ 1400mA |

| Lumens Per Watt: | 80 lumens @ 60 watts |

| Colour Temp: | 2700K, 3000K and 4000K |

| CRI Warm White (3000°K): | 85+ |

Ultra Bollard Light Engine

| LED Chip: | 5x Cree XPG-3 Plug and Play, field replaceable PCB boards |

| Output: | 1200 lumens @ 1400mA |

| Lumens Per Watt: | 80 lumens @ 3 watts (per XTE) |

| Colour Temp: | 2700K, 3000K and 4000K |

| CRI Warm White (3000°K): | 85+ |

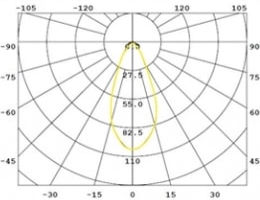

25° TIR Lens

25° TIR Lens

45° TIR Lens

60° TIR Lens

About Us

Newsletter

Useful Links

Terms & Policies

Shortcuts

Translate Site